With the work salary increase, it is high pressure for textile industry. Another side ,the spinning environment, treatment and night duty, these kind of factor is negative. The lack of labor is very common is whole textile industry.

In China, total spindle number is over one hundred million .At present, only 10% ring frame have doffing fuction,90% ring frame need to modificate for doffing ,specially the short ring frame not have doffing function. So must increase the automatic control level asap and reduce the labor number sharply. The ring frame must have doffing function as standard configuration.

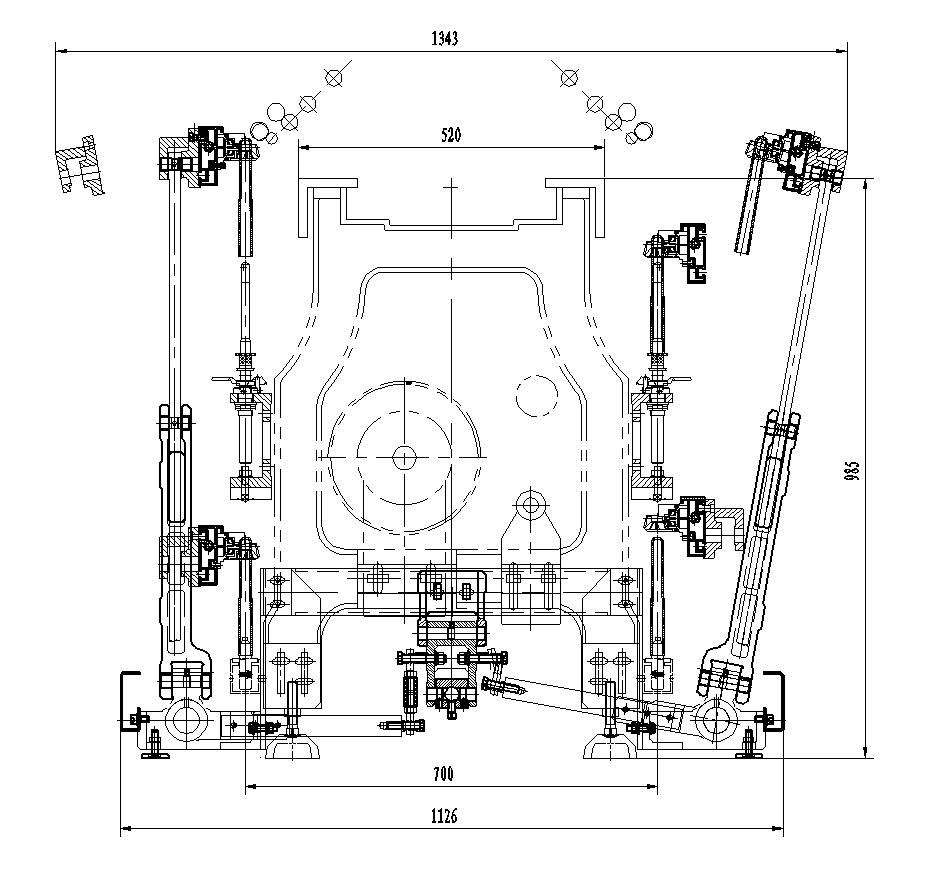

Replacement new ring frame is not true in spinning factory, but through modification ring frame is reliable by automatic doffing, insert bobbin, transportation bobbin.

Through modification for doffing, can increase equipment efficiency sharply, improve yarn quality and reduce labor use. It is the best solution for customer to deal with labor and quality problem.

CN

CN EN

EN